#Product Trends

Building with recycled plastic products

Lightweight slabs with U-Bahn® Beton for sustainable construction

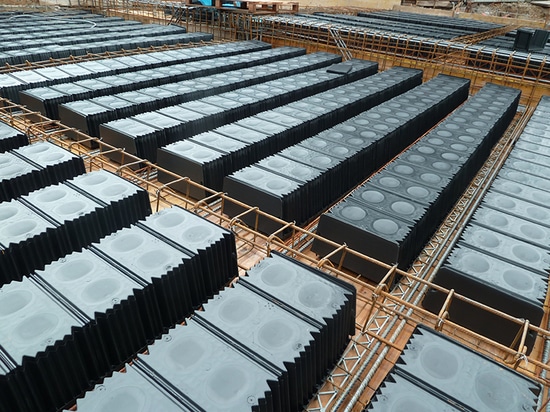

In modern construction, the search for innovative and sustainable solutions is an increasingly pressing challenge. In this scenario, lightweight slabs with U-Bahn® Beton stand out as a high-performance answer with an environmentally conscious approach. Made from recycled plastic, U-Bahn® Beton modular formwork is a clear example of a circular economy. The benefits of this technology are not limited to the environmental aspect but offer several concrete advantages in terms of construction efficiency.

Why choose U-Bahn® Beton for a one-way lightweight floor slab?

As a lightweight and stackable void former, U-Bahn® Beton offers great design flexibility. Unlike brick piñatas and polystyrene former, it creates a cavity through which cables and installations can pass.

PERFORMANCE ADVANTAGES

Maximum versatility

U-Bahn® Beton also allows the production of precast slabs, further reducing construction time and labour costs.

High precision and uniformity

U-Bahn® Beton void former guarantees perfect concrete rib geometry for optimum structural performance.

Improved site cleanliness

The compact and modular nature of U-Bahn® Beton void former helps to minimize waste and debris on site, ensuring a cleaner and safer working environment.

Improved seismic performance

The presence of a double reinforced concrete shell gives U-Bahn® Beton slabs greater rigidity and seismic resistance, making them ideal for areas with a high seismic risk.

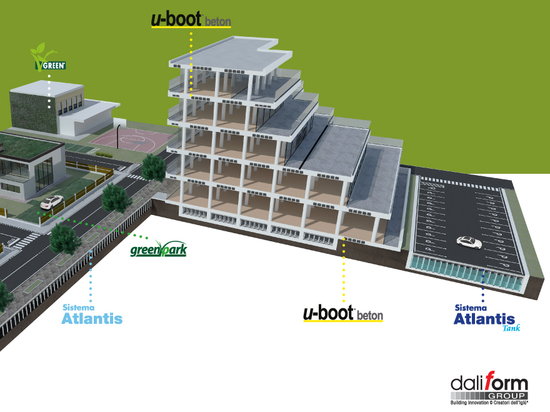

APPLICATIONS

U-Bahn® Beton is the ideal solution for lightened one-way slabs, for all types of buildings: residential, commercial, office, industrial, but also for public buildings such as schools and hospitals.

U-Bahn® Beton is basically used in all applications where one-way slabs and floors are required, and where concrete and weight savings are required.

A particular type of use is in underground construction using the so-called "top-down" technique, where instead of working from the bottom up (as in normal open-air construction), the load-bearing slabs are built from top to bottom, alternating the construction of the slab with the excavation of the lower level. Underground car parks in historic city centers are often constructed using this technique due to the obvious constraints of the presence of numerous buildings adjacent to the excavation and the need to restore the road system quickly.