#Industry News

Europerfil establishes a sustainable alliance with Tecnalia Certificación for environmental product verification

Driving transparency and sustainability in the industry.

Europerfil, a company of the ArcelorMittal group, leader in innovative solutions for steel metal sheets & slats for construction, polyurethane and Polyisocinaurate sandwich panels and Polyisocinaurate insulating plates, is proud to announce a strategic collaboration with Tecnalia Certificación, a product certification entity 100% owned by Fundación Tecnalia Research & Innovation. Together they have carried out a Life Cycle Analysis (LCA) study in accordance with ISO 14044 and, subsequently, a rigorous process of development and verification of Environmental Product Declarations (EPD®), in accordance with the General Instructions of the International EPD System Program (v3.01) and product category rules PCR 2019:14 Construction products (EN 15804:A2) Version 1.11.

This alliance covers and applies to a wide range of products currently manufactured by Europerfil, including:

36 references of steel-based metal sheets & slats with multiple end-use applications, such as: enclosure on simple roofs & in-situ sandwich, facing on simple façades & in-situ sandwich, lower support on deck-type roofs & collaborative slab.

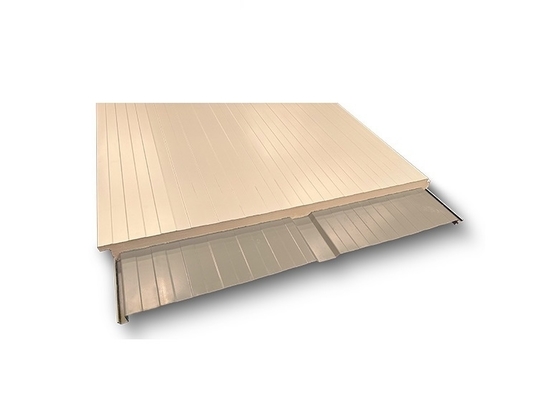

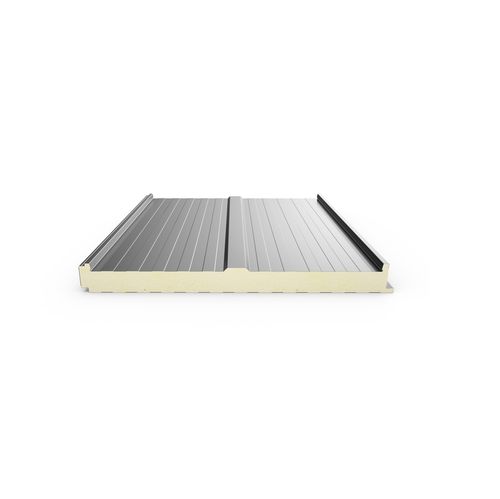

26 references of polyurethane (PUR) and polyisocyanurate (PIR) sandwich panels suitable for installation on roofs, façades and as enclosures in freezer and deep-freeze conservation chambers.

3 references of polyisocyanurate (PIR) plates with different facings for use as a thermal insulation layer and waterproofing support in metal deck-type roofs.

Europerfil and Tecnalia Certificación are dedicated to promoting sustainable practices in the industry. This collaboration emphasizes the joint commitment to transparency, guaranteeing safe products for customers, innovative and in accordance with the Paris Agreement and the European Green Deal. Therefore, in addition to carrying out the LCA and the development of the subsequent EPD®, based on the use of steel manufactured in a conventional furnace, the complete study has also been carried out based on the XCarb® Recycled and Renewably Produced Steel , which is based on a substrate that contains at least 75% recycled material and is manufactured in an electric oven powered exclusively by renewable energy sources, obtaining, in this second case, a notable reduction in terms of CO2 emissions equivalent / m2 of functional unit manufactured, compared to the use of steel manufactured in a conventional furnace.

Without a doubt, and for all this, Europerfil and Tecnalia Certificación: the best alliance to contribute to the reduction of the carbon footprint of buildings.