#Product Trends

Ever thought about just how small sintered glass mosaic art can get?

Meet the smallest sintered glass mosaic chips on the market!

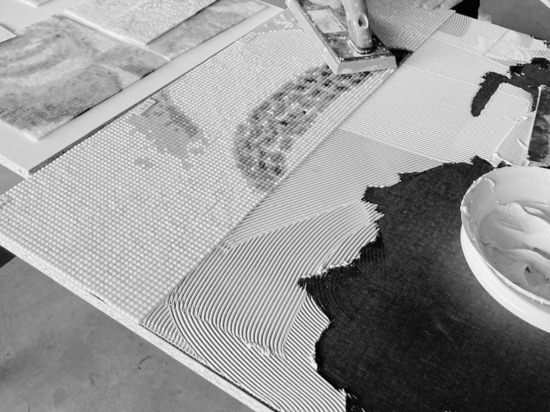

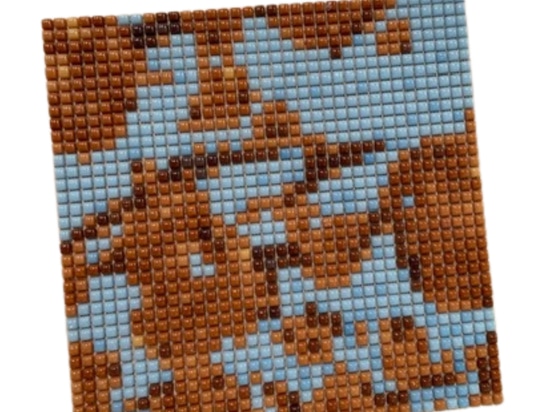

When it comes to creating intricate, durable, and visually stunning mosaic surfaces, sintered glass is setting a new standard. The availability of as tiny as 4.8 mm x 4.8 mm sintered glass mosaic chips is a groundbreaking advancement for architects, designers, and mosaic artists, enabling them to achieve extraordinary detail, precision, and aesthetic impact in their projects.

What Is Sintered Glass and Why It Matters

Sintered glass is created through a specialized process that involves compressing powdered glass at high temperatures to form a dense, durable material. This method produces a non-porous, scratch-resistant surface with impressive resilience against environmental wear, making it ideal for high-traffic and moisture-prone areas. Its durability, paired with a refined, consistent finish, ensures that sintered glass mosaics stand out for both beauty and function.

The Innovation of Smaller Mosaic Chips

Traditionally, mosaic chips have been manufactured in standard sizes, typically around 20x 20 mm or 10 x 10 mm. However, with the development of sintered glass mosaic chips as small as 4.8 mm x 4.8 mm, artisans and designers can now incorporate fine details into their work with unparalleled precision. These miniature mosaic tiles are particularly beneficial for applications requiring detailed designs, such as complex geometric patterns, intricate murals, and high-definition reproductions of artwork.

Advantages of Small Sintered Glass Mosaic Chips

The introduction of these smaller sintered glass chips brings several advantages for professional applications:

• Enhanced Detail and Precision: This level of precision is ideal for projects where every detail matters, whether in custom artwork, branding, or architectural installations.

• Durability Meets Aesthetic Flexibility: Sintered glass’s inherent durability ensures that even these tiny chips are resistant to chips, scratches, and fading.

• Environmental and Economic Efficiency: Due to its non-porous surface, sintered glass is less prone to absorbing stains or chemicals, minimizing maintenance. This makes it an eco-friendly option for sustainable design, as it’s long-lasting and requires fewer resources over time.

Conclusion

The world of mosaic design has entered a new phase, and with the availability of the smallest sintered glass chips on the market, there’s no limit to the level of detail and durability that can be achieved.