#Product Trends

complex pillars

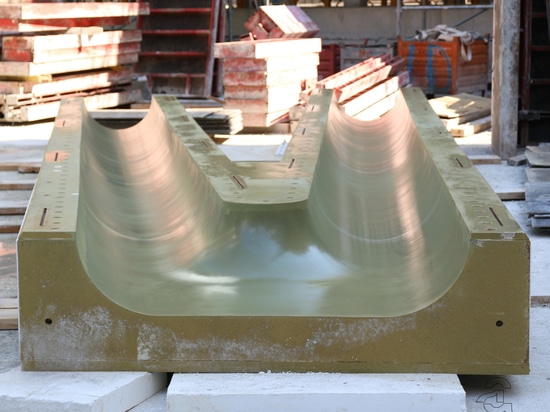

In the heart of Milan we have helped to create a very special "V" pillar.

Let's see some numbers on this pillar and on the solution proposed for its realization

- more than 8 meters high

- 600mm diameter of the column

- 120KN / sqm of compressive strength of the polystyrene used

- 3 reuses sustained by the formwork

The delivery to the construction site took place with a special transport and subsequently stored on the ground

The surface of the polystyrene was coated with our resin suitably treated to obtain a good quality facing.

Once the iron was placed, the formwork was closed with its half. The system we have studied takes the name of "Rapidoget" and is defined as self-supporting.

You can see it in detail https://arbloc.it/casseforme/casseforme-per-colonne/

The system designed by our technicians contributes to a "hermetic" closure of the formwork, restoring a clean joint.

The resin-coated surface in contact with the concrete, on the other hand, is responsible for the quality of the casting.

The preventive study is essential in the construction of complex formworks to prevent any problems of use on site.

Regardless of the complexity of the formwork to be made, we believe that the technical study is crucial for a good final result and for customer satisfaction.

Contact us to submit your intervention

and visit the section of our site dedicated to construction companies